Volkswagen has announced that it will soon begin producing nearly all components of its electric vehicle drivetrains in-house, cutting down on the number of major parts required from external suppliers.

At present, although it produces its own batteries and electric motors, it still relies on other firms to produce important components of its EV powertrains, most notably pulse inverters and thermal management systems

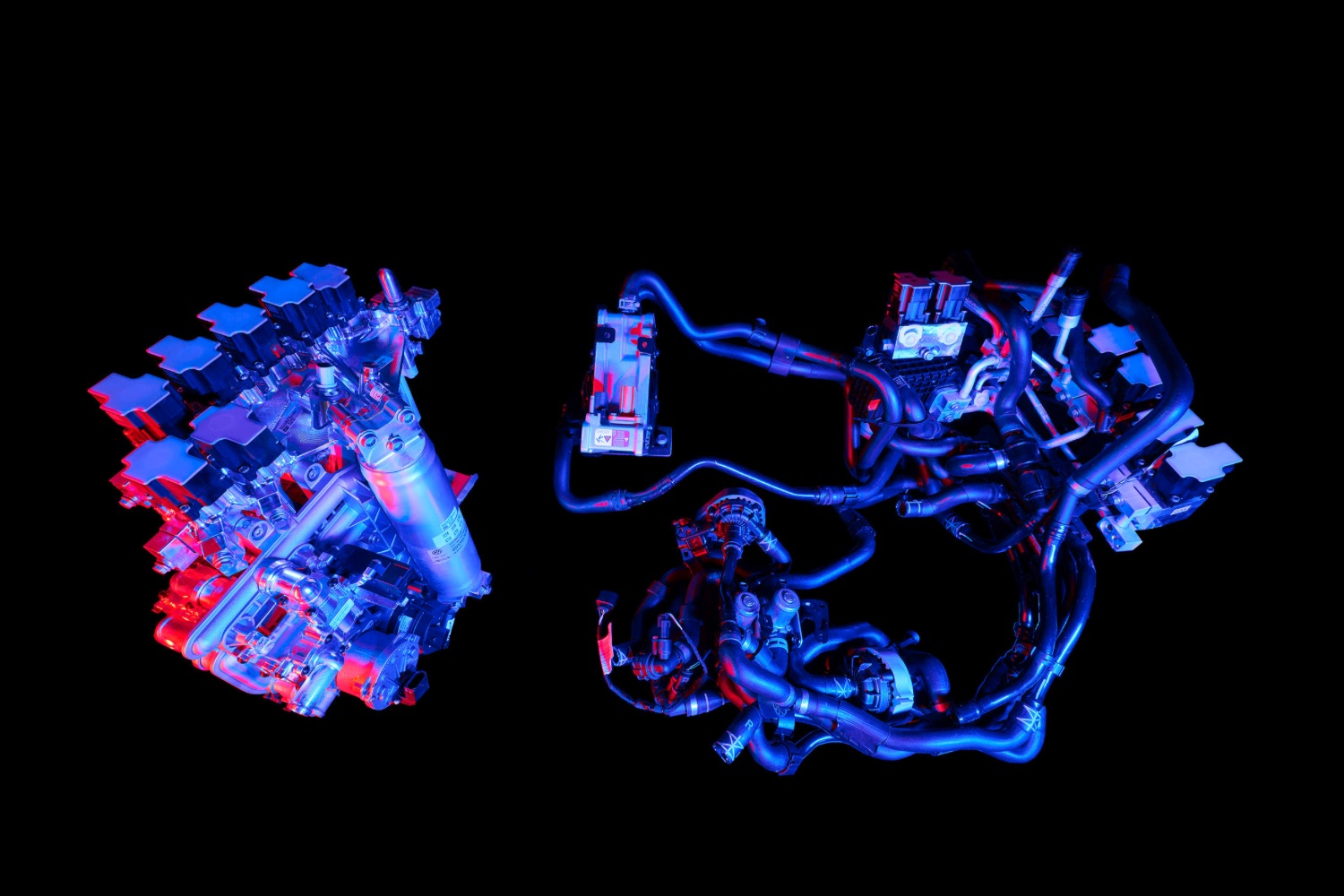

Crucial components

A pulse inverter converts the DC current flowing from the high-voltage battery into three-phase power suitable for use by the motor making it a crucial piece of an EV drivetrain in terms of efficiency and reliability.

Volkswagen has said, however, that it has designed its own pulse inverter, with engineers developing the hardware and software aspects from the ground up. The firm says that its inverters could potentially be used in all kinds of vehicles from entry-level EVs to high-end electric sports cars with nearly 700hp. Development of the component is currently underway, and though it's not yet ready to be rolled out, it will, the company says, make an appearance as part of the next-generation of its MEB modular electric car platform.

VW is also working to produce its own thermal management system for EVs - one which, by relying on a single, compact thermal management unit rather than several individual units and long, unwieldy hoses aims to be lighter, more effective and more efficient. As well as controlling the air-conditioning, the thermal management system will also help warm or cool the battery pack, having a significant impact on the vehicle's range and fast-charging ability.

Economies of scale

The sheer size of the VW Group, it says, will allow it to leverage economies of scale, making it cost-effective to develop and produce its own pulse inverters and thermal management systems as well as providing it with an increased security of supply, something about which VW learned the hard way when Russia's invasion of Ukraine cut off important parts of the firm's supply chain leaving it without vital parts such as wiring looms.

"The Volkswagen Group and its brands stand for first-class products and technologies," said the company's new boss, Oliver Blume.

"Thanks to the size and breadth of the Group, as well as our in-house expertise, we can leverage enormous economies of scale. This benefits our customers and makes our vehicles even better."

Blume's sentiments were echoed by fellow VW Group board member Thomas Schmall.

"Our goal is to achieve technological leadership, also in electric mobility," said Schmall.

"That's why here, too, we rely on our internal competencies and, after battery cells and electric motors, we are taking over the development of pulse inverters and thermal management systems. In future, this will make the Volkswagen Group one of the only car manufacturers in the world that's able to offer a holistically optimised complete system."