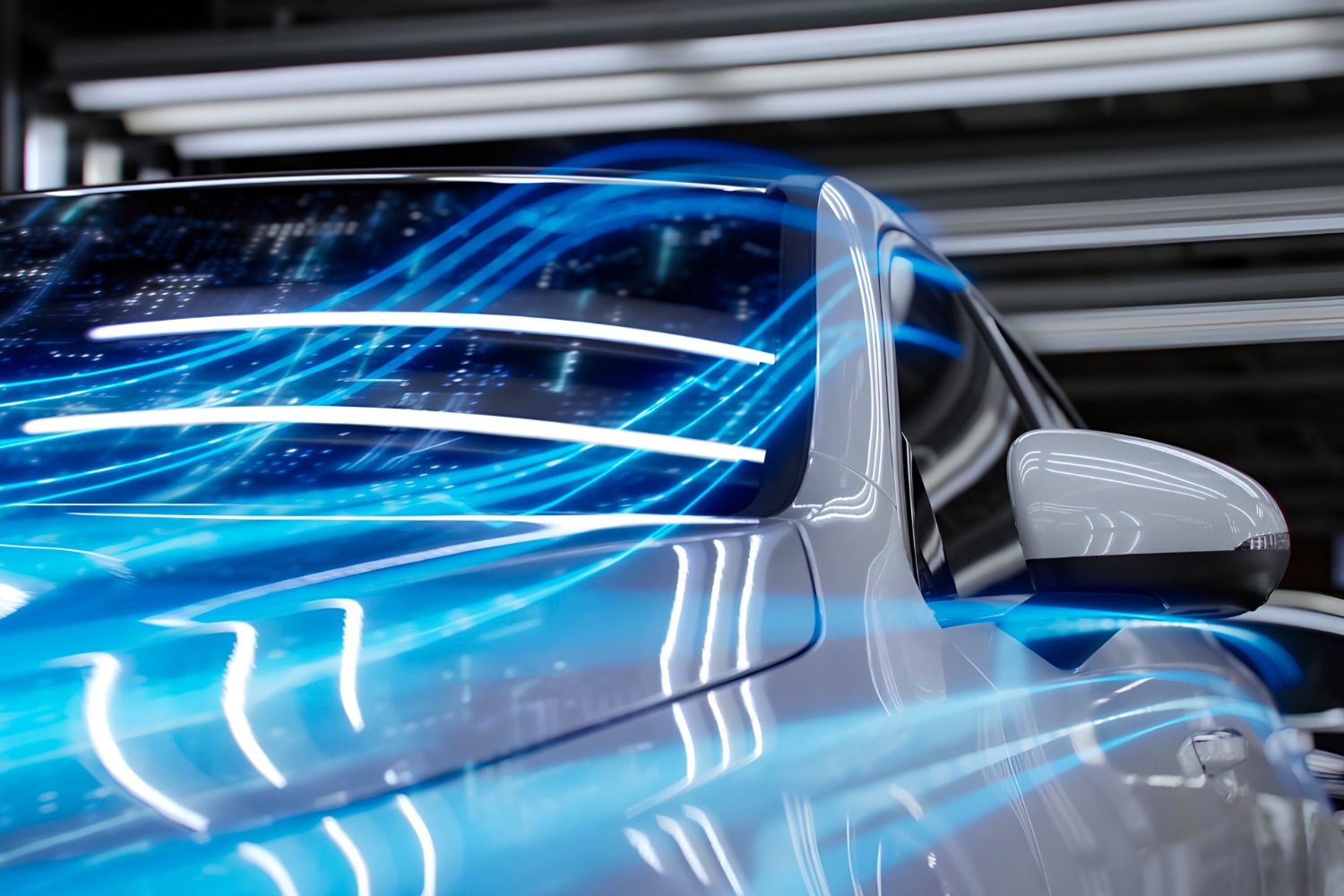

Mercedes is gearing up to produce a whole new generation of electric cars based on its new MMA - that's Mercedes Modular Architecture - platform. We've seen the first product of this new setup already, or at least sort of. The CLA concept shown at the recent Munich motor show will, by 2025, morph into the first production model based on MMA and will also become Mercedes' rival to the Tesla Model 3 and BMW's incoming 'Neue Klasse'.

Four new MMA models

To get this new car into production - not to mention the CLA Shooting Brake and the new GLA and GLB that will also be built using the MMA platform - Mercedes is turning to the latest digital production tools that will, the company hopes, dramatically speed up the process between design and the first customer cars rolling off the line.

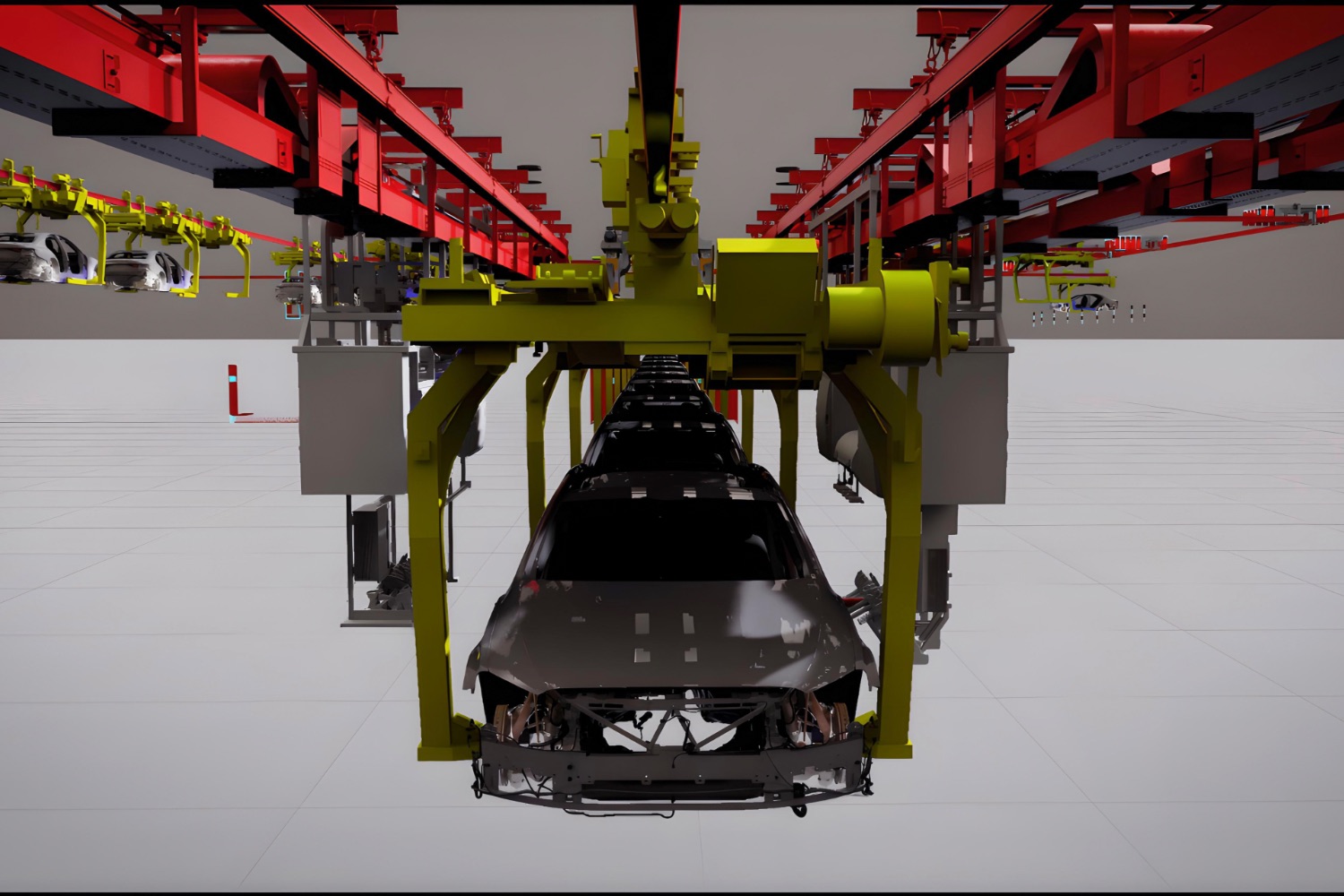

Three factories have been earmarked for models using MMA - Rastatt in Germany, Kecskemét in Hungary, and Beijing in China. All three will use what's being called the new Mercedes-Benz MO360 production system, and that entails creating what's called a digital twin of the production process in each factory.

Mercedes is working with tech company NVIDIA to design this process, which basically creates a perfect model of the factory, the cars, and the systems used to build the cars in cyberspace. That way, the 'perfect' digital model can be compared to the imperfect physical reality, and any potential bugs ironed out before they cause problems in the real world - or so at least goes the theory.

Working out the bugs

Mercedes reckons that using the digital twin setup can cut the number of steps and stages it needs to prep the three factories for MMA production by around half. "Using a digital twin doubles the speed for converting or constructing an assembly hall - while improving the quality of the processes. With the data collected in the virtual world, assembly processes can be optimized even faster and potential errors can be detected at an early stage - without "real world" interference", said a Mercedes spokesperson.

"What if reality becomes a representation of the digital, rather than the digital being a representation of reality? Our vision in the future is getting trust in digital twins as same as we do in physical reality," said Jan Brecht, Chief Information Officer (CIO) of Mercedes-Benz.

"Digitalization will enable a whole new era of efficiency for the automotive industry. Using NVIDIA Omniverse and AI, Mercedes-Benz is building a connected, digital-first approach to optimize its manufacturing processes, ultimately reducing construction time and production costs," said Rev Lebaredian, Vice President of Omniverse and simulation technology at NVIDIA.

AI boosts energy savings

On top of the whole digital twin idea, Mercedes will also be rolling out AI - artificial intelligence - to help speed up and smooth out its in-factory processes. According to Mercedes, the Rastatt plant is being used to pioneer digital production in the paint shop. AI, it seems, has helped to create efficiency gains in topcoat booths, where vehicle chassis get their paint and protection layers. Instead of using conventional computer-controlled systems, Mercedes let AI take over, which led to energy savings of 20 per cent when compared to conventional setups. It's even using a ChatGPT project to help identify and flag possible production defects.

All of this also feeds through to the software that will be used in the MMA cars. This will be Mercedes' new in-house Mercedes-Benz Operating System (MB.OS), and the new factories will be able to constantly update the software in the cars as they're being built so that each one rolls off the end of the production line with the most up-to-date software possible. In theory, the MB.OS can also be not merely updated over the air - which is becoming standard practice anyway - but can be updated much more quickly, almost constantly, enabling Mercedes to quickly fix and patch any potential bugs, as well as roll out new features on the fly.

It's all linked up to the Mercedes Intelligent Cloud, or MIC, which has an "intelligent analysis interface so that every employee can read and analyse the current software status of any vehicle in the network using the MO360 Data Platform. This is supported by an app for intelligent defect diagnosis - a predictive failure prevention. The app detects potential errors at an early stage and uses an intelligent algorithm during the production process to provide instructions for quality assurance."

"Mercedes-Benz is initiating a new era of automotive manufacturing thanks to the integration of Artificial Intelligence, MB.OS and the digital twin based on NVIDIA Omniverse into the MO360 ecosystem. With our new 'Digital First' approach, we unlock efficiency potential even before the launch of our MMA models in our global production network and can accelerate the ramp-up significantly", said Jörg Burzer, Mercedes' head of quality and supply chain management.